Committed to Circularity in Medical Devices

VinylPlus® Med is a European initiative dedicated to collecting and recycling non-contaminated polyvinyl chloride (PVC or vinyl) medical devices, transforming them into new, high-quality products for the healthcare sector. Led by VinylPlus Healthcare, the programme works with Veolia for logistics & waste management, De Loods, a social enterprise that dismantles the devices, and Raff Plastics, which ensures their recycling into high-quality recyclate.

Currently, VinylPlus Med collaborates with around 20 hospitals, all located within a 200 km radius to minimise transport emissions and reduce the carbon footprint of medical waste recycling.

Tackling Medical Plastic Waste Through Circularity

Vinyl (PVC) is the most widely used plastic in single-use medical devices, including oxygen masks, tubing, and IV bags. While essential for patient care, a significant portion of this waste remains clean and non-contaminated—yet most of it is still incinerated or sent to waste-to-energy facilities.

European healthcare systems contribute 5–10% of national carbon footprints, with medical devices and pharmaceuticals accounting for nearly half. Addressing waste at the source—by improving sorting between infectious and non-infectious materials and prioritising mechanical recycling for highly recyclable vinyl—is increasingly recognised as a key decarbonisation strategy. Where needed, vinyl is also compatible with chemical recycling technologies such as pyrolysis.

Pioneering Healthcare's Circular Plastic Economy

VinylPlus Med was launched in February 2022 to provide a practical mechanical recycling solution for non-contaminated, REACH-compliant vinyl medical waste, building on the success of the UK-based RecoMed programme. The initiative piloted in Belgium and is now expanding to France, helping hospitals reduce incineration, improve waste management, and contribute to a circular economy.

By creating a scalable model for medical vinyl recycling, VinylPlus Med is addressing one of the biggest challenges in healthcare sustainability: diverting high-quality plastic waste from incineration while maintaining safety and efficiency in hospital environments.

Is It Safe to Recycle Medical Vinyl?

Yes! The VinylPlus Med recycling system is designed for clean, non-contaminated vinyl waste, following strict hygiene protocols – similar to how deposit return schemes for bottles work.

The risk of contamination is minimal, as the devices collected:

- Have not been in contact with infectious materials

- Are used in controlled medical environments, such as elective surgeries

Clear hospital guidelines, posters, and intensive staff training ensure that only approved vinyl medical waste is placed in the dedicated bins. Strict hygiene procedures are in place throughout the process to ensure safety not only in hospitals but also for social partners, waste handlers, and recyclers.

The Circular Journey of Medical Vinyl

The high-quality, colorless medical vinyl waste collected at VinylPlus Med hospitals follows a structured recycling process, ensuring that valuable material is transformed into new, durable products for the healthcare sector.

After use, non-contaminated vinyl medical devices are collected in dedicated bins throughout the participating wards and transported to our social partner which carefully removes non-vinyl parts before the clean vinyl is sent for recycling.

The material is then processed into high-quality recyclate, which can be used to produce vinyl wall coverings and other long-lasting healthcare products.

Vinyl wall covering, made with regrind vinyl, is hygienic, dimensionally stable, and resistant to chemicals. Its durability and shock-absorbent properties make it ideal for protecting hospital walls from collisions with beds and equipment while contributing to a holistic architectural design.

Currently, the recyclate is being tested for use in new hospital flooring.

Step-by-Step: The VinylPlus Med Recycling Process

USE OF MEDICAL DEVICE

The medical device is used by patients for elective surgery and other treatments where the waste remains non-contaminated.

COLLECTION

Filled bins provided by VinylPlus Med are collected by waste management companies.

DISMANTLING

Our social partner, De Loods Nekker, dismantles the devices, removing non-vinyl parts.

RECYCLING

Our recycling partner, Raff Plastics, processes the waste.

USE OF RECYCLED VINYL

The recycled vinyl is used for wall covering and other durable products for the healthcare sector.

Full Recycling Process (3 min)

Recycling Process in 36 Seconds

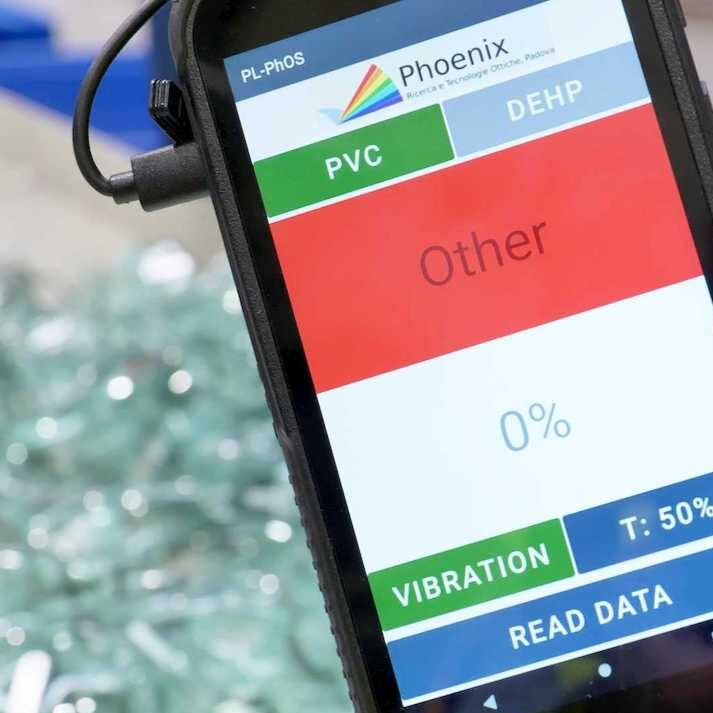

Smart Scanner Ensures Only REACH-Compliant Waste is Recycled

It is crucial for the success of VinylPlus Med that only REACH-compliant, DEHP-free vinyl is recycled. To meet this objective, a cost-efficient portable near-infrared (NIR) scanner has been developed by the European vinyl industry.

The scanner, which uses artificial intelligence (AI) to detect the presence of vinyl (PVC) and DEHP in waste streams, is currently being improved and scaled up to enhance its accuracy and efficiency. The long-term plan is to integrate the scanner into recycling plants, ensuring an automated and streamlined sorting process for medical and other flexible vinyl waste streams.

Third-Party LCA Documents Significant CO2 Reductions From Mechanical Recycling

To quantify the carbon savings achieved through VinylPlus Med’s recycling efforts, French consultancy Ecovamed conducted a Life Cycle Assessment (LCA) on vinyl-based medical tubing in Europe. This assessment followed the GHG Protocol standard and compared two end-of-life scenarios for medical tubing:

- Incineration with energy recovery and acid flue gas treatment

- Mechanical recycling in Belgium, with an 80% material yield, producing wall coverings from the recovered vinyl.

The LCA found that, on a cradle-to-grave basis, mechanical recycling reduces greenhouse gas emissions by 25% compared to incineration, equivalent to 2.0 kg CO₂eq avoided per kg of tubing. If the recycled vinyl were fully utilised in other applications with higher vinyl content, the potential CO₂ savings could be significantly higher than those currently calculated.

New Study Confirms Recyclability of Medical PVC

A Strong Network

Discover all hospitals collecting PVC medical devices and our partners in the map:

Partnering with Stakeholders for Healthcare Plastic Circularity

VinylPlus Med is also partnering with broader initiatives to advance circularity in healthcare plastics. One example is Select4Care, a Belgian project focused on improving the collection, sorting, and recycling of medical plastic waste while also developing design-for-recycling guidelines. As part of its commitment to increasing the recyclability of medical vinyl, VinylPlus Med contributes its expertise in material circularity and waste logistics to this initiative.

Another example is the synergy between our partners Veolia and De Loods, who, in addition to handling the logistics and dismantling of VinylPlus Med plastic waste from hospitals, also collaborate on other healthcare recycling schemes such as PP blue wraps and PS serology trays. Their joint efforts help optimise every step of the recycling chain – from on-site collection and sorting to material recovery – ensuring that recyclable plastics are efficiently returned to the loop.

Our Partners

Raff Plastics

Raff Plastics, being ISO 9001 and EucertPlast certified, has pioneered high-quality recycling of PVC in Belgium since 1981 and produces 50,000 tonnes of plastic recyclate each year.

Discover why Raff Plastics became a VinylPlus Med partner in the interview with Co-Owner and Manager Carolina Van der Perre below.

De Loods

Our social partner, De Loods, carefully removes non-vinyl parts from medical devices, ensuring that clean, high-quality vinyl is sent directly to recycling. This meticulous process at our waste dismantling hub supports both the social and environmental pillars of sustainability.

Veolia

Veolia facilitates the collection and logistics of non-infectious vinyl medical waste in the VinylPlus Med initiative. They ensure that the waste is efficiently transported from participating hospitals to the social partner, De Loods Nekker, where non-vinyl components are removed. After sorting, Veolia then manages the transfer of clean vinyl waste to Raff Plastics, where it is processed into high-quality recyclate for new, durable healthcare products.

Hospitals in the VinylPlus Med Scheme

What They Say About Us

Ghent University

VinylPlus Med mentioned as an example of already existing initiatives in Belgian hospitals to collect and recycle disposables.

BX1

CHU St Pierre announced that the hospital could collect 150 kg PVC in 3 months and that VinylPlus Med will be applied in all departments by end-2023.

Inovyn Awards 2022

Bronze in Circularity category: VinylPlus for its ‘collection and recycling process targeting non-infectious PVC medical consumables’

Le recyclage des déchets hospitaliers en PVC prend son envol en Belgique: “Notre hôpital est, comme bien d’autres, un gros pollueur.”

Le PVC est le plastique le plus largement utilisé dans les dispositifs médicaux jetables: masques, tubulures… Le projet VinylPlus Med, qui vise à trier les applications médicales en PVC pour les recycler, vient d’être lancé chez nous. Objectif : 1000 tonnes par an!

Trends/Tendances

VinylPlus Med, un projet commun de recyclage des déchets médicaux en équipement hospitalier.

Trois structures unissent leurs forces pour accroître la durabilité dans le secteur des soins de santé en Belgique. A terme, le projet collaboratif VinylPlus Med devrait permettre d’éviter l’émission de 2.000 tonnes de CO2 par an grâce au recyclage des déchets médicaux.