Polyvinyl chloride (PVC or vinyl) is essential in pharmaceutical research, manufacturing, and distribution, ensuring hygiene, durability, and efficiency across the supply chain. It supports sterile medical equipment, laboratory surfaces, manufacturing processes, power and data transmission, fluid management, energy-efficient infrastructure, cold chain logistics, and pharmaceutical packaging. From research facilities to production plants and global distribution networks, vinyl provides reliable, high-performance solutions that meet the stringent demands of the pharmaceutical industry.

Key Pharmaceutical Applications

Sterile Medical Equipment

Vinyl is widely used in medical-grade tubing, fluid bags, and containers, ensuring safe and contamination-free storage and transfer of pharmaceuticals. Its flexibility, transparency, and chemical compatibility make it an ideal material for use in sterile environments, supporting critical medical and research applications.

Laboratory Safety and Hygiene

Vinyl provides durable, easy-to-clean surfaces for flooring, wall coverings, and countertops in pharmaceutical research facilities. Its chemical resistance and seamless installation help maintain sterile environments, reducing the risk of contamination and ensuring compliance with hygiene standards.

Efficient Manufacturing Processes

Vinyl plays a crucial role in pharmaceutical manufacturing, providing durable and hygienic solutions such as conveyor belts, protective barriers, and flexible hoses. These components contribute to smooth and contamination-free production, ensuring the safe and efficient handling of raw materials and finished products.

Durable Fluid Management

PVC pipelines ensure safe and efficient fluid management in pharmaceutical production. Chemical-resistant process pipes withstand exposure to harsh substances, preventing corrosion and contamination. Clean water distribution pipes deliver high-purity water for pharmaceutical formulations, while sewage and wastewater pipes provide leak-proof and long-lasting drainage solutions, ensuring compliance with hygiene and safety standards.

Cold Chain Logistics

Vinyl enhances pharmaceutical logistics with truck tarps that protect shipments from weather and UV exposure, and strip curtains that maintain stable temperatures in cold chain transport. Flexible vinyl hoses ensure safe liquid and air transfer, while gaskets, door seals, and anti-corrosion coatings prevent contamination, moisture ingress, and mechanical damage, ensuring secure and efficient pharmaceutical distribution.

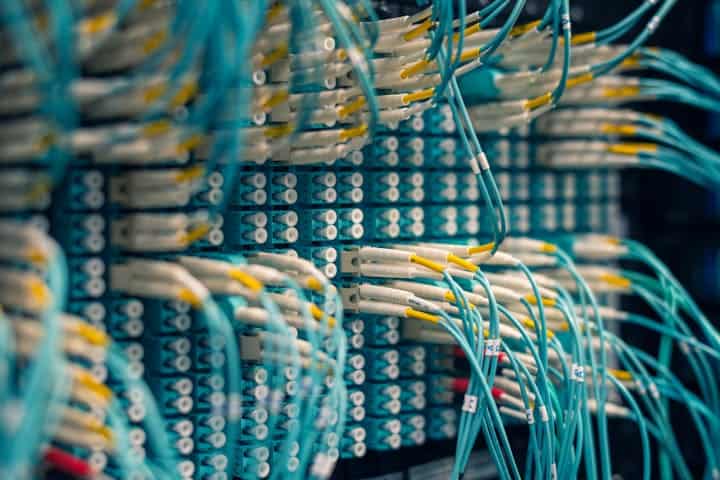

Reliable Power and Data Transmission

PVC cables ensure fire-safe, reliable electrical and data transmission in pharmaceutical research and manufacturing facilities. Their excellent insulation and self-extinguishing properties protect critical systems from electrical faults and ensure uninterrupted operations in controlled environments.

Energy-Efficient Buildings

Vinyl enhances energy efficiency in pharmaceutical manufacturing plants, warehouses, and research facilities through durable roofing membranes and high-performance window profiles. Vinyl roofing membranes are leak-resistant, fire-safe, and reduce heat absorption, improving the efficiency of solar panels and overall energy performance. PVC window frames and doors offer excellent insulation, helping maintain stable indoor temperatures, reducing energy consumption, and improving working conditions in controlled environments.

Pharmaceutical Blister Packaging

PVC is the industry standard for pharmaceutical blister packaging, ensuring product safety, durability, and efficiency. Rigid PVC films, often coated with PVDC or combined with aluminium foil, provide excellent barrier protection against moisture, oxygen, and contaminants, preserving medication stability and extending shelf life. PVC blister packs also enable precise unit-dose dispensing, improving patient compliance and reducing medication waste.

Ongoing sustainability initiatives, such as VinylPlus® PharmPack, are advancing the recyclability of PVC blisters, reinforcing their role in a circular pharmaceutical supply chain.

Cleanroom Doors

PVC is used in both swing and roll-up doors across pharmaceutical facilities to ensure hygiene, durability, and workflow efficiency. Flexible swing doors provide hands-free access in high-traffic areas, while PVC roll-up doors enable fast, airtight separation between clean zones. Both options are easy to clean, resistant to chemical exposure, and ideal for maintaining strict contamination control.